Explain the Different Types of Welding Positions With Neat Sketch

MIG Gas Metal Arc Welding GMAW 5. The four main types of welding are.

Types Of Welding Positions Welder Portal

Flat horizontal vertical and overhead.

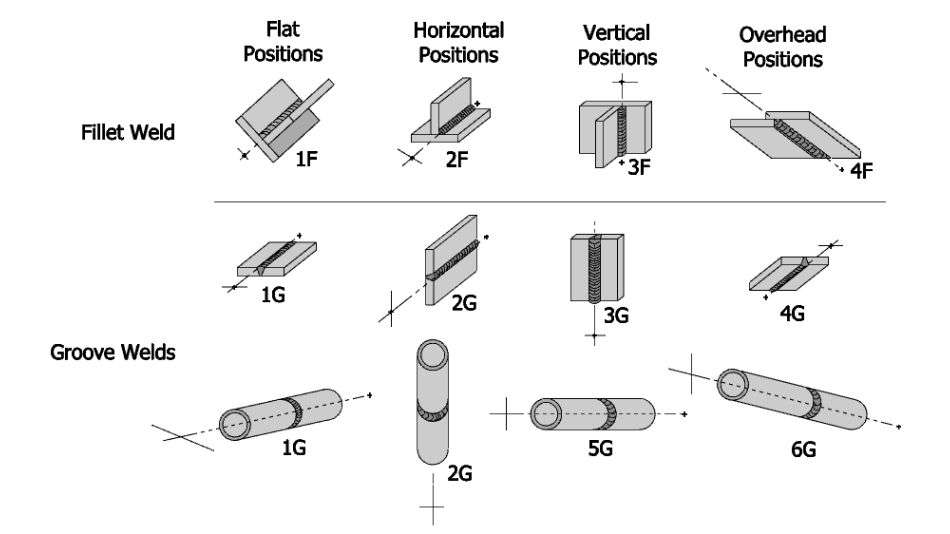

. 1G 2G 3G 4G 5G and 6G6GR. This type of weld is probably the easiest type to do as it consists of two flat pieces that are attached parallel to each other in a side-by-side fashion. The Four Basic types of welding positions are Flat horizontal vertical and overhead welding positions.

Principles and Applications MindTap Course List 8th Edition. Flat Position 1G and 1F Horizontal Position 2G and 2F Vertical Position 3F and 3G Overhead Position 4G and 4F 1. What are the different types of welding processes and its applications.

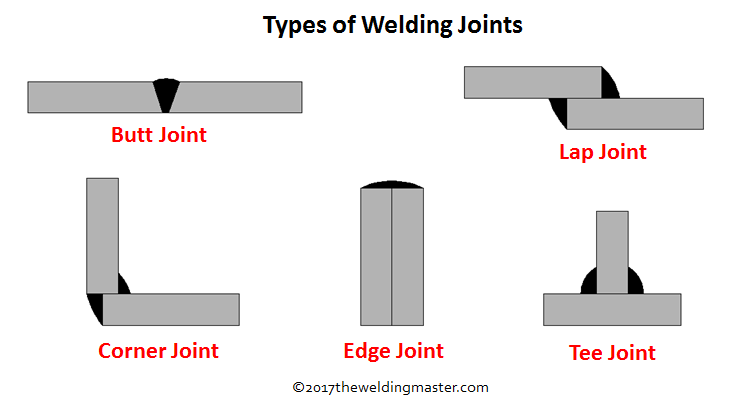

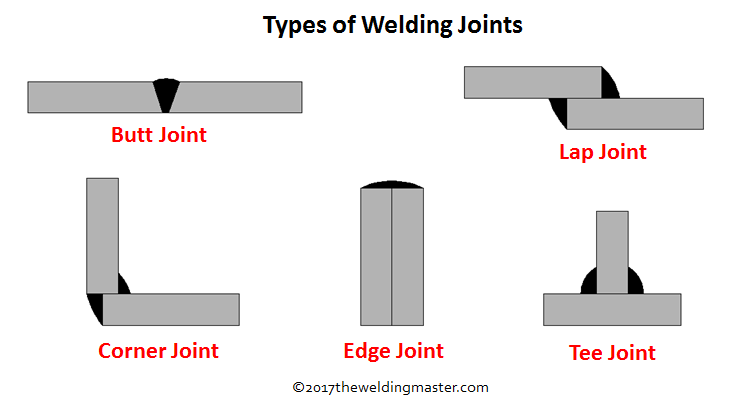

Other variations exist as well - for example double-V preparation joints are characterized by the two pieces of material each tapering to a single center point at one-half their height. The position of a particle traveling along a curved path is s. There are 5 Types of Welding Joints and the Picture.

Following are the four main types of welding positions. The lap joint is obtained by over lapping the two plates and welding the edges of the plates. This type of joint is the most commonly used welding joint.

The tee joint is as the name describes a joint in the shape of a T. First week only 499. The positions flat horizontal vertical and overhead are the basic types of welding positions.

1 Introduction To Welding 2 Safety In Welding 3 Shielded Metal Arc Equipment Setup And Operation 4 Shielded Metal Arc Welding Of Plate 5 Shielded Metal Arc Welding Of Pipe 6 Shielded. Since the joining is an intermixture of metals. Socket weld flange 2.

The manner in which the joining occurs is dependant on the exact process used for example friction stir welding FSW friction stir spot welding FSSW linear friction welding LFW and rotary friction welding RFW. This type of weld is the most common type that is used in automated welding. The most common type of weld you will do is a Fillet weld and a Groove weld and you can accomplish these welds in all four positions.

Pipe and Plate Weld Joint Positions. All the positions are used in various angles and shapes while performing welding. Below are the six types of welding joints.

The five basic types of weld joints are the butt joint lap joint corner joint edge joint and T-joint a variant of this last is the cruciform joint. The four basic welding positions are. A butt joint is a joint that is used when two pieces of metal are to be welded together side by side.

Start your trial now. In this post well detail the specifics assigned to each process and highlight the differences among them. There are five basic types of joints commonly used for fusion arc and gas welding.

This involves welding at the top of the joint. Flux-Cored Arc Welding FCAW 3. Arc welding explained below Carbon arc welding Metal arc welding Gas metal arc welding MIG Plasma arc welding.

Plasma Arc Welding 8. Arc welding is one of several fusion processes for joining metals. Gas welding Oxy acetylene or hydrogen welding explained below Air acetylene welding 2.

Lap welding joints are essentially a modified version of the butt joint. There are three basic types of gas welding flame. Upon cooling and solidification a metallurgical bond is created.

One piece of metal lays down flat while another section is welded standing on its. Types Of Welding Joints. Laser Beam Welding 6.

Atomic Hydrogen Welding 9. The Types of Welding Joints. The styles used for creating corner joints include V-groove J-groove U-groove spot edge fillet corner-flange bevel-groove flare-V-groove and square-groove or butt.

For example an oxidizing flame produces oxidation while a carburizing flame produces iron carbide. Flat Position Welding In the flat welding position the welding is performed on the top side of the joint. Normally there are six welding positions with certain numbers and letter ie.

Pipe 3Socket weld elbow 4Fillet weld 5Expansion gap. However they do not adequately describe pipe welding positions. Welding defects are formed in a welding work due to the weak or poor technique used by the inexperienced or untrained welders or due to structural problems in the welding operation.

Fusion welding or nonpressure welding explained below They can also be classified depending on the source of heat as follows. Stick Shielded-Metal Arc Welding SMAW 4. TIG Gas Tungsten Arc Welding GTAW 2.

Types of Welding Positions by AWS and ASME. By applying intense heat metal at the joint between two parts is melted and caused to intermix directly or more commonly with an intermediate molten filler metal. The 9 Types of Welding 1.

ASME B311 1998 1273 Preparation for Welding E Socket Weld Assembly says. The types of flame are named based on the chemical effect on the material being welded. Its relatively easy to prepare and there are many variations that can be applied to manipulate the desired result.

Friction welding doesnt require the use of. Let us discuss these types of welding positions in details. Assignment1 Explain the Importance of Welding Process.

In assembly of the joint before welding the pipe or tube shall be inserted into the socket to the maximum depth and then withdrawn approximately 116 16 mm away from contact. 2 Explain with neat sketch Gas welding process. Different Kinds of welding Positions GROOUL Face Groove angle -FOOT Root gap - Root face Fillet WeLDS a Flat Positions b HORIZONtal P Positions P 2 Horizontal P1 WELDING P 2 Vertical Positions d over Head positions P2 PI vertical axis Generally over P1 Plate 1 the Head P2 Plate 2 2 Attachments jpg jpg Comments 1.

These positions well cover in a separate article. However the actual face of the weld is approximately horizontal. Gas Metal Arc Welding GMAWMIG Gas Tungsten Arc Welding GTAWTIG Shielded Metal Arc Welding SMAW and Flux Cored Arc Welding FCAW.

Flat Position The most obvious type to perform is the flat position sometimes called the down hand position. It is used to joint the plates having thickness 3 mm or less. Pipe welding can be done under many different requirements.

But you also do surface welds in all four positions as well thought you will not do this type of weld very often.

Different Types Of Welding Joints The Welding Master

What Are The 5 Mig Welding Positions A Definitive Guide Welders Lab

No comments for "Explain the Different Types of Welding Positions With Neat Sketch"

Post a Comment